Standpipes/Fill Points

Servicing All of QLD & NSW

From Queensland to New South Wales, Forcequip delivers mine ready hardware, technical advice, and local supply hubs to supporting mining projects.

Hardware Expertise

Custom Fabrications

Technical Advice

Local Supply Hubs

Standpipes/

Water Truck Fill Points

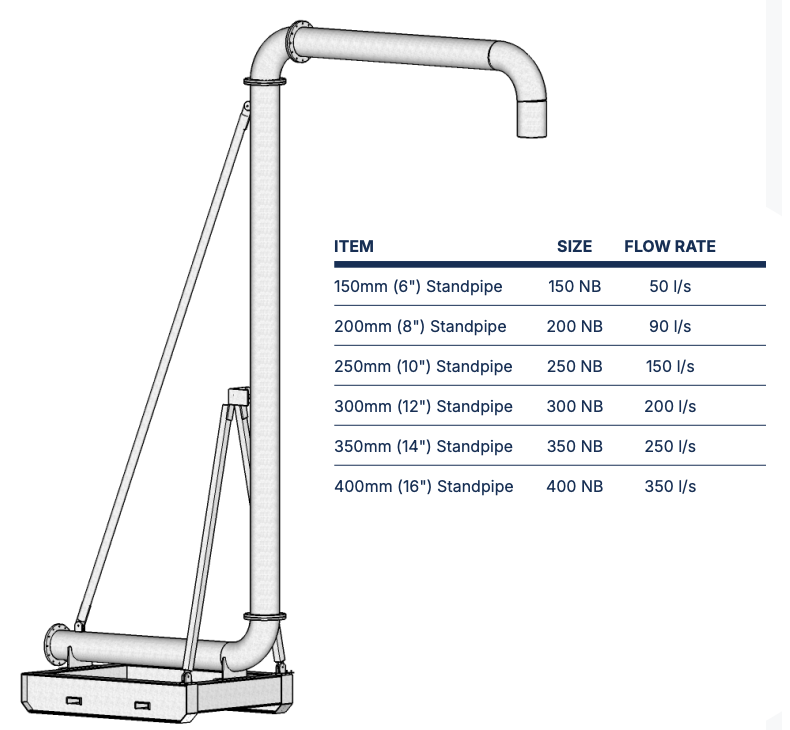

Forcequip’s standpipes are purpose built for mining applications, designed to handle high flow rates and tough site conditions. Engineered for durability and ease of use, they’re available in multiple size and reach combinations to suit varied fleet setups. Built specifically for mining, our standpipes help operators reduce fill times and keep dust suppression operations running efficiently.

Key benefits of our range include:

- Multiple sizes available from 150mm to 450mm

- Strong construction suited to mining applications

- Designed for towable applications

- Simple integration into existing pumping networks

These features help operators reduce downtime, improve site efficiency, and maintain water access. By focusing on mine ready design and straightforward supply, Forcequip ensures projects run without unnecessary delays.

Call us today to discuss standpipe options for your operation.

Our Products

Designed for Smooth Operations

Efficient water access is essential for mine sites, and Forcequip supplies standpipes and water truck fill points designed for smooth operations in Queensland and New South Wales. Available in sizes ranging from 150mm to 450mm, these units are built to handle heavy duty use while ensuring safe and consistent water distribution. Their robust construction makes them suitable for demanding mining and industrial conditions where reliability is critical.

Forcequipʼs Australian designed and manufactured water truck fill points are purpose built for the mining industry. Available with or without concrete-filled bases, our designs suit the full range of Caterpillar, Hitachi, Liebherr and Komatsu water carts.

Built tough for durability, safety and efficiency, they deliver reliable performance in dust suppression and haul road maintenance under the harshest conditions.

Call 1300 286 105 today to arrange standpipe supplies for your site.

Contact Us Today

Thank you for contacting Forcequip.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Frequently Asked Questions

Understand how standpipes and fill points operate, with useful details that assist in water access, distribution, and ongoing site efficiency.

Why are standpipes available in different diameters?

Different diameters, such as 150mm to 450mm, accommodate varying site demands. Larger diameters allow faster water transfer, while smaller sizes provide controlled flow. The choice depends on truck capacity, system requirements, and operational efficiency needs.

How do water truck fill points improve site efficiency?

Water truck fill points provide fast and reliable access to large water volumes. They reduce refilling times, minimise downtime, and support consistent site operations, especially in dust control and processing, where continuous water supply is essential.

What maintenance do standpipes require?

Standpipes require routine inspections for leaks, wear, and structural integrity. Maintenance may include replacing seals, checking valve operation, and ensuring fittings remain secure. Regular servicing extends their lifespan and maintains reliable water delivery across mining operations.