Steel Spools and Fittings

Servicing All of QLD & NSW

From Queensland to New South Wales, Forcequip delivers mine ready hardware, technical advice, and local supply hubs to supporting mining projects.

Hardware Expertise

Custom Fabrications

Technical Advice

Local Supply Hubs

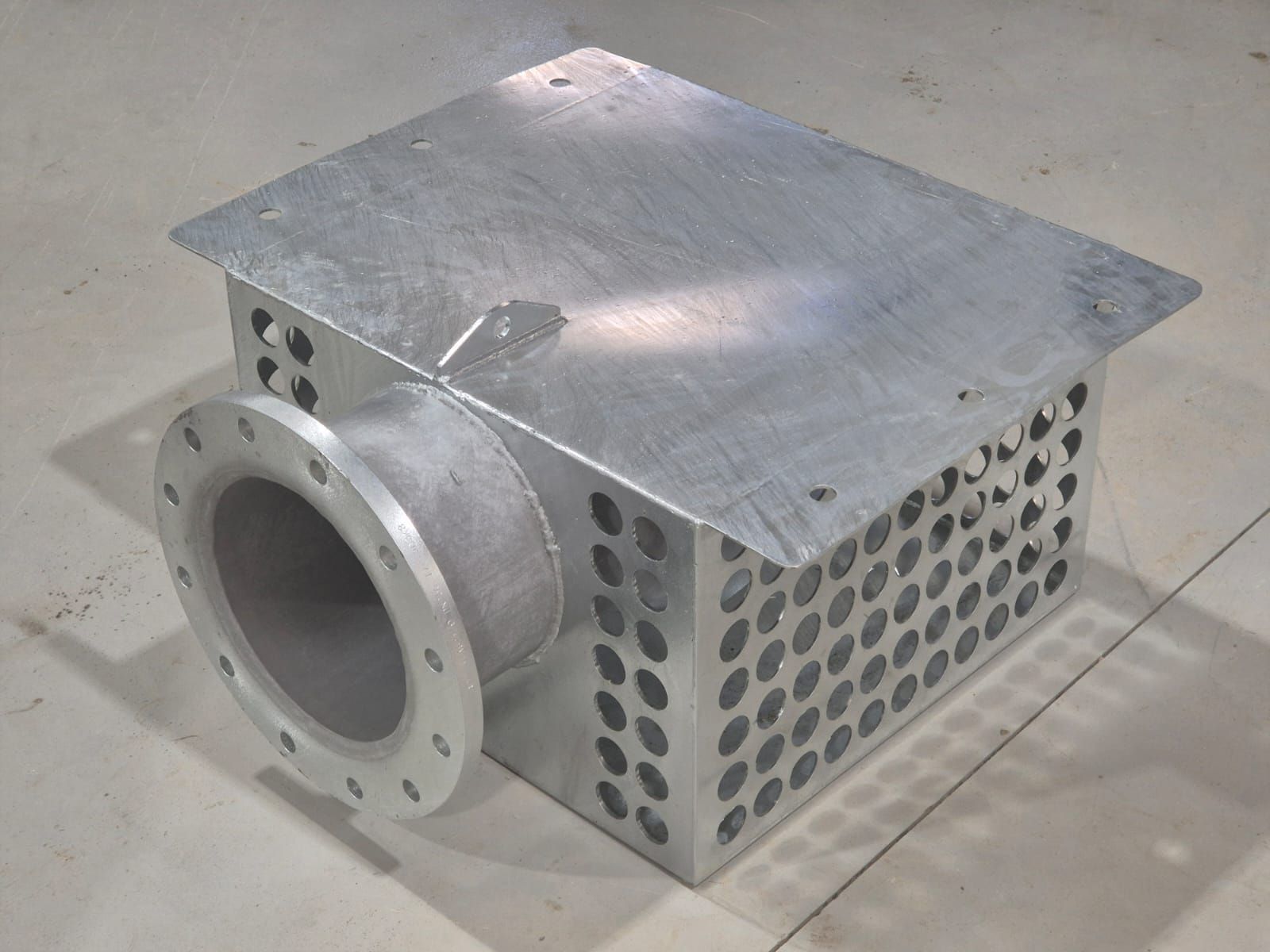

Steel Fittings, Spools & Manifolds

Key advantages of our equipment include:

- Custom Design and Fabrication

- Control over Fabrication process to ensure faster production times.

- Galvanized, Painted or Stainless Steel options

Call Forcequip today to secure poly products that reduce downtime and improve operational flow.

Our Products

Ensuring Consistent Performance

Forcequip designs and fabricates custom pipe manifolds, spool assemblies, and fittings engineered for high-pressure applications in CHPP, slurry, and water processing systems. Our in house capabilities include detailed design, precision welding, and fabrication in galvanized, painted, or stainless steel. We offer onsite inspections, measure ups, and consultation to ensure every solution meets site specific requirements and performance standards. Whether it’s a new installation or a retrofit, Forcequip can for fill your requirements.

We work with project managers, engineers, and site operators to deliver Water management systems that match exact site requirements. From Standard Reducers, TEES and Y spools through to fully custom manifolds, Forcequip can deliver on your requirements.

Call 1300 286 105 today to arrange supply for your project.

Contact Us Today

Thank you for contacting Forcequip.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Frequently Asked Questions

Discover key information about steel pipes, spools, and fittings, with practical insights to support safe and efficient operations.

What is a water manifold and how does it work?

A manifold is a header that splits one supply into multiple controlled outlets or combines several lines into one. It balances flow across branches, typically using isolation valves, gauges and non-return valves. Good manifolds minimise pressure drop, prevent backflow, and make maintenance easier by allowing sections to be shut off.

What are spool assemblies used for in piping systems?

Spool assemblies simplify installation by providing pre-fabricated pipe sections with fittings and flanges attached. This reduces onsite welding, speeds up system setup, and ensures accurate dimensions, improving efficiency and reducing downtime in mining and industrial piping applications.

What material is best for a manifold?

Choose by pressure, temperature, media and environment. Carbon steel suits high pressure and rugged sites; stainless resists corrosion and chemicals; HDPE is lightweight, impact-resistant and ideal for buried or portable duty; PVC fits lower-pressure, clean water indoors. Consider UV exposure, abrasion, chemical compatibility, and whether you need field-welded or modular assembly.